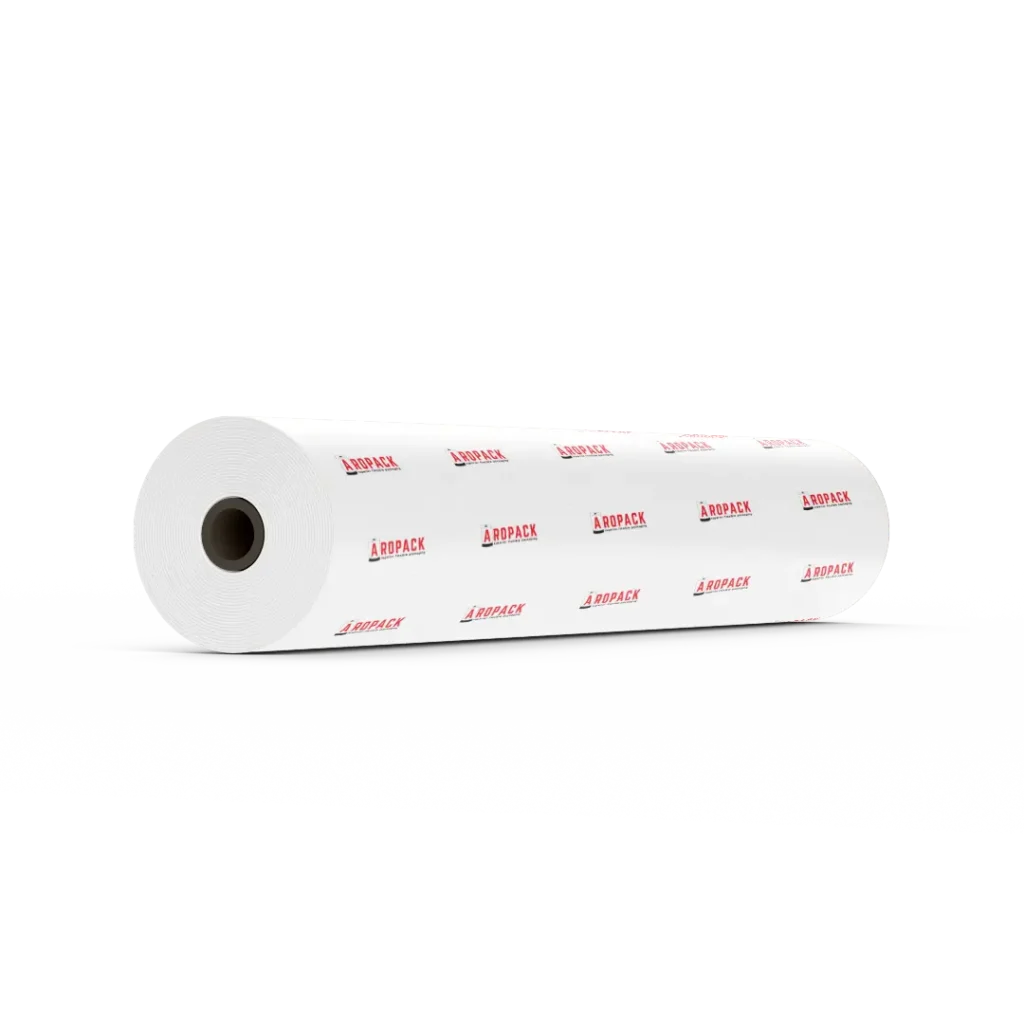

Retort Pouch

Retort pouch is a thin and lightweight way of flexible packaging format suitable for ready meals to be heated in the microwave and are suitable for sterilisation.

For hot fill applications, our retort pouch packaging can undergo sterilisation in pressurised tanks at temperatures of up to 131°C before being packaged.