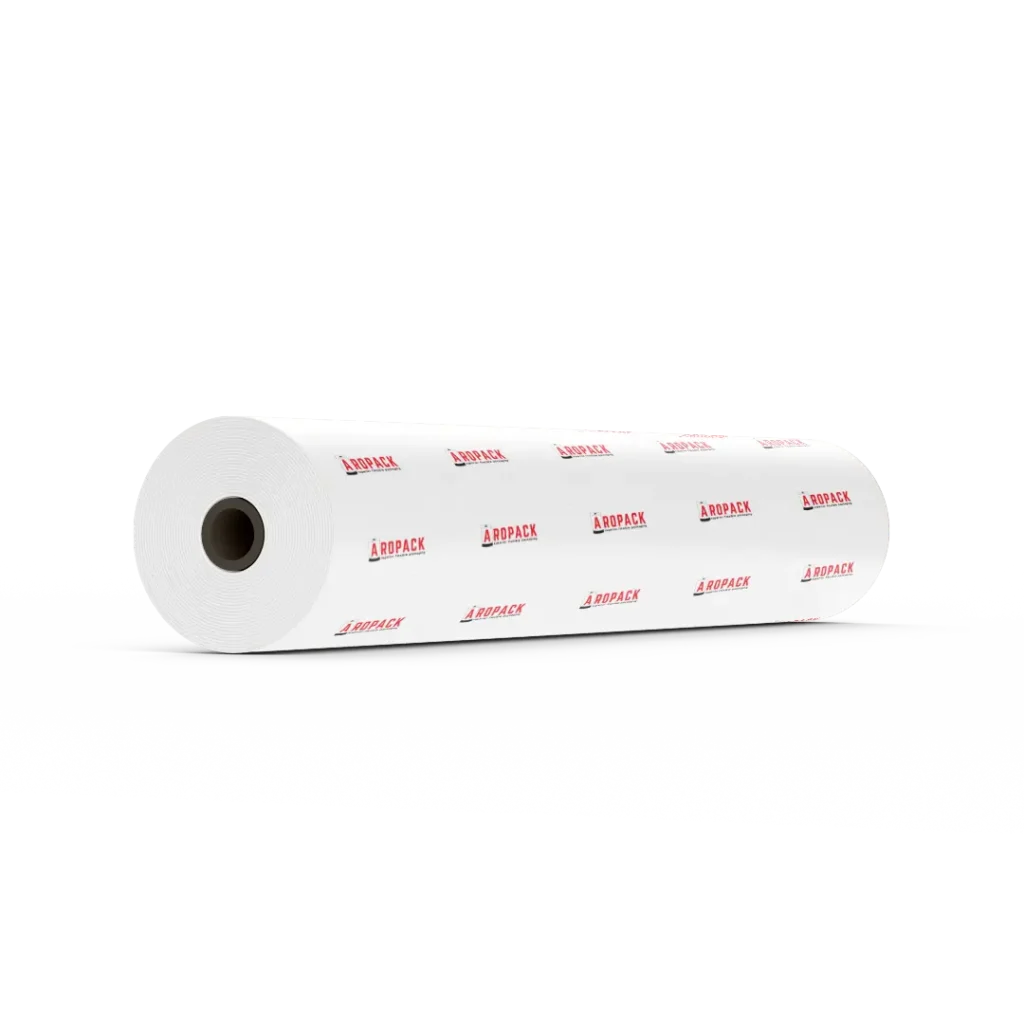

Ovenable Film

Our ovenable films are performance films for oven and microwavable applications. They can withstand temperatures up to 200⁰C for 90 minutes and feature laser perforation for steam release. It comprises a high-performance polyester film laminate on a reel, suitable for standard packing lines and ultra-high cooking temperatures.