Sustainability is no longer a side project for UK brands. It shapes how you design products, talk to retailers, and win consumer trust. At Aropack, we specialise in sustainable packaging that cuts material use, protects your product, and fits the way the UK collects and recycle packaging.

Sustainable Packaging

What is sustainable packaging?

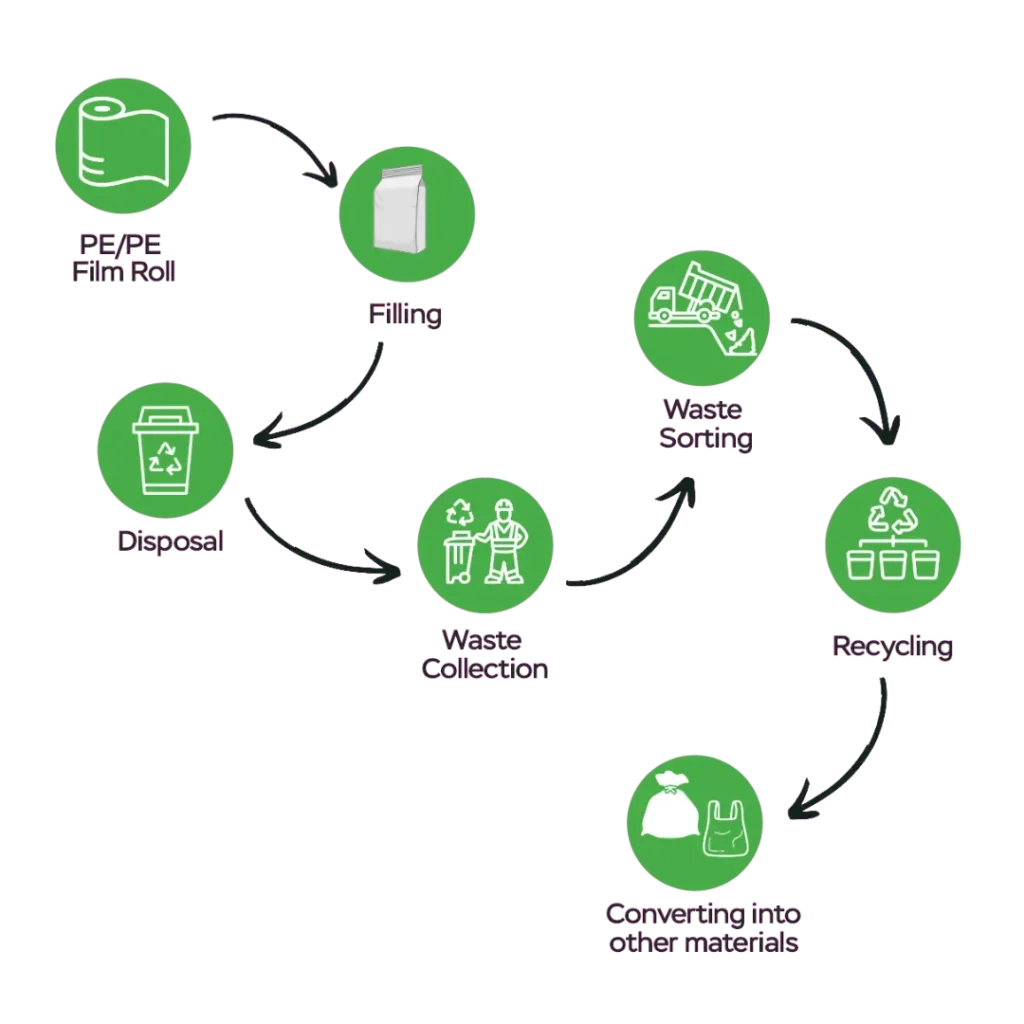

Sustainable packaging is not just “made from eco material”. It is packaging that is designed to keep its total environmental impact as low as possible across its whole life cycle: from raw materials and film production through printing, filling, transport, use and end of life. UK guidance increasingly links “sustainable” to how well a pack minimises climate impact, resource use and waste while still doing its job in the real world.

In practical terms, sustainable packaging is packaging that:

check_circleUses as little material as possible for the protection it provides.

check_circleKeeps products safe and extends shelf life so product waste is reduced.

check_circleIs compatible with real collection, sorting and recycling or recovery systems.

check_circleBalances environmental performance with food safety, product protection and commercial viability.

What sustainable packaging means at Aropack?

Our sustainable packaging solutions are designed to reduce environmental impact while maintaining the quality, barrier protection, and branding flexibility your product demands. From mono material flexible packaging to recyclable materials for food packaging, we make it easier to go green, without giving up performance.

For Aropack, sustainable packaging mainly means high performance flexible films and pouches that:

check_circleReduce material and transport weight compared with rigid formats.

check_circleMaintain the barrier, seal strength and durability your product needs.

check_circleAre designed to work with current and emerging UK recycling systems.

check_circlePrioritise recyclable mono material PE and PP structures where technically and commercially suitable.

%97

Customer Retention

Why flexible packaging plays a key role in sustainability?

As sustainability becomes a key driver for conscious consumers and retailers alike, brands are rethinking their packaging.

Whether you are moving from rigid tubs to pouches or upgrading existing films to mono material structures, we help you choose specifications that balance performance, cost, and environmental impact.

Lighter packs, lower footprint

Compared with rigid options such as jars, tins or tubs, flexible packaging typically uses far less raw material and space, which reduces resource use, transport emissions and the overall environmental footprint per packed unit.

Protecting products and preventing waste

Because most of the environmental impact usually sits in the product rather than the pack, high barrier flexible packaging that keeps products intact and fresh can significantly cut waste and the hidden footprint of lost ingredients, manufacturing and logistics.

Built for modern circular design

With the shift from multi material laminates to recyclable mono material PE and PP structures designed for real film recycling systems, modern flexible packaging is increasingly aligned with circular economy goals while still providing downgauged, high performance protection.

Our Sustainable Packaging Options

Every product, filling line and waste stream is different, so “sustainable” cannot be a single material choice. At Aropack we work with a focused set of sustainable packaging materials that balance performance, cost and environmental impact while keeping one eye firmly on how packaging is actually collected and processed in the UK.

Every product, filling line and waste stream is different, so sustainable cannot be a single material choice. At Aropack we work with a focused set of sustainable packaging materials that balance performance, cost and environmental impact while keeping one eye firmly on how packaging is actually collected and processed in the UK.

Our core sustainable range is based on mono material PE and PP structures that are engineered for recyclability without losing the strength and shelf life your product needs. Our sustainable packaging can be done in pouch formats such as stand up pouches, flat bottom and quad seal bags, pillow packs and film on a reel, helping brands move away from hard to recycle mixed laminates while keeping a familiar look, feel and packing process.

For products that need extra protection against oxygen, moisture or light, we specify high barrier mono material structures that combine carefully selected barrier layers, coatings and sealing layers in a single polymer family. This approach protects sensitive products such as coffee, snacks or pet food while still supporting recyclability where the local infrastructure allows.

For specific applications where composting is a realistic end of life route, we can supply certified compostable and bio based films and pouches made from renewable raw materials. These solutions are used selectively, in projects where the product, waste system and brand story genuinely support a compostable route rather than using it as a generic sustainability claim.

Why Choose Aropack as Your Sustainable Packaging Supplier

At Aropack, we specialise in mono material PE and PP pouches that are engineered for UK and European recycling systems while still delivering the barrier, seal integrity and shelf life your products need. Our team combines technical packaging expertise with guidance on when recyclable pouches are the right solution and how to align them with OPRL and local collection schemes. We also support our clients test runs to full scale production across stand up, flat bottom, quad seal, 3 side seal and spouted pouch formats.

Got questions about our sustainable packaging?

We’ve answered the most common technical and practical questions about our sustainable packaging options.

Mono material flexible packaging is made from a single polymer type — like PE/PE or PP/PP — rather than multilayer laminates that mix incompatible materials. This structure makes the pouch easier to recycle through existing waste streams, especially where facilities support LDPE or PP recycling. It’s a key innovation in sustainable packaging optionsthat balances performance with recyclability.

We offer PE-based and PP-based films for recyclable materials for food packaging, all suitable for direct food contact. These structures meet shelf-life and barrier needs while remaining compatible with designated recycling classes like LDPE-4 or PP-5. They’re ideal for dry goods, snacks, or food packaging pouches where circularity matters.

The key is choosing environmentally friendly packaging materials that align with your product’s shelf-life requirements. We help balance function (like barrier, seal strength, and machinability) with sustainability — offering compostable, recyclable, or downgauged packaging products as needed.

Compostable packaging breaks down under specific conditions (often in industrial composters), while recyclable structures can be reprocessed into new materials through standard recycling systems. We primarily focus on recyclable materials for food packaging as they’re more widely supported and stable in terms of barrier and shelf life.

Transitioning often requires small adjustments in filling equipment, heat sealing, or storage conditions. But we work closely with clients to ensure the new sustainable packaging materials function reliably at every stage — from production to the end customer.

Not at all. Whether you choose mono material flexible packaging or paper-based structures, we ensure high-resolution, full-colour printing. Our digital and gravure presses are optimised to perform across sustainable substrates with sharp detail and excellent shelf appeal.