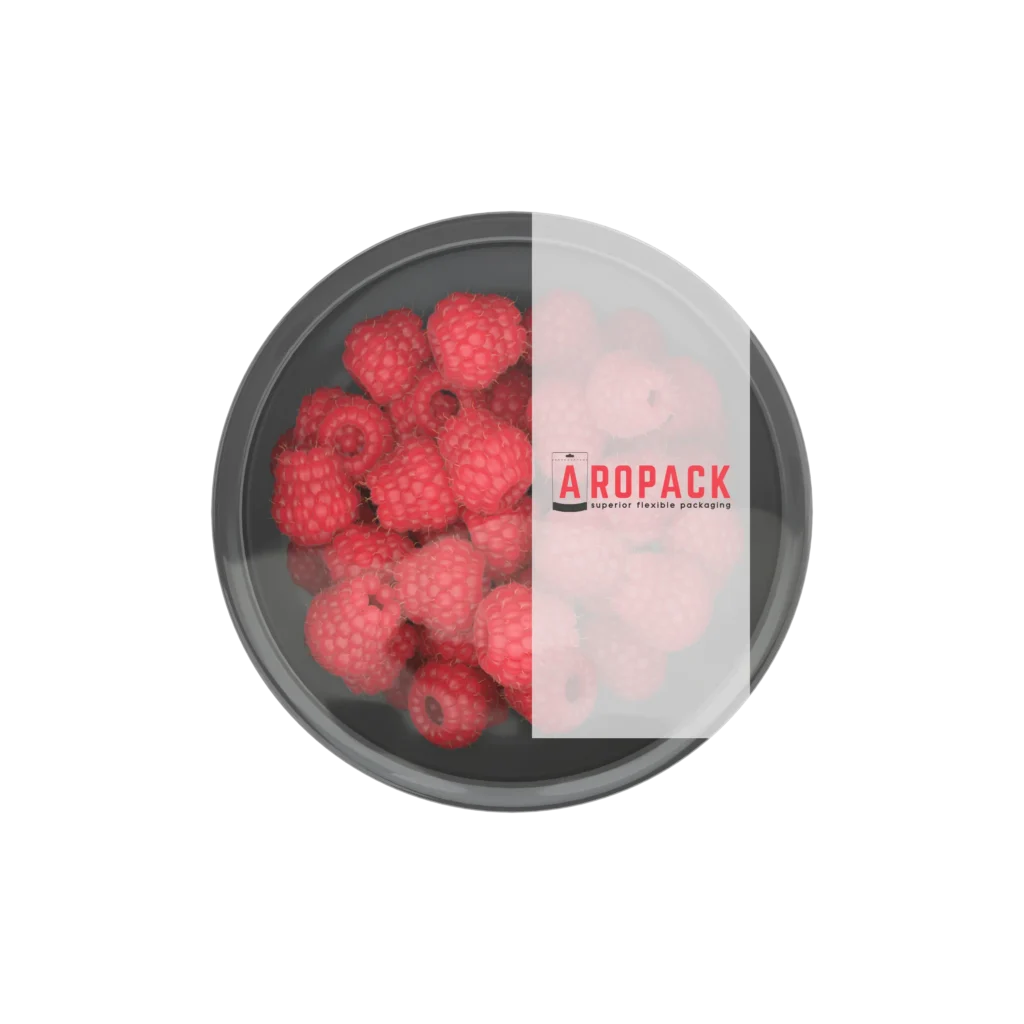

Lidding Film

Our lidding films provide excellent oxygen barrier protection with tamper-evident seals. We produce high-barrier lidding for thermoform packaging machines and top film solutions, ensuring efficient operation on your packing lines, whether printed or unprinted.

If you are unsure about the right lidding film for your application, contact one of our team members for expert guidance on matching substrates.