Retort pouches are the unsung heroes of modern food packaging. Lightweight, shelf-stable, and heat-resistant, they’re designed to safely package ready-to-eat meals, sauces, rice, soups, and more — all while withstanding intense sterilisation. But what exactly makes retort pouch packaging perform so well? And what should you look out for when choosing the right packaging solution for your product?

A retort pouch is more than just a flexible plastic bag. It is a carefully engineered packaging option designed to perform under high temperature, high pressure, and intense mechanical stress. Success depends not only on the materials used but also on the pouch design, sealing precision, and alignment with the filling and sterilisation process.

What is a Retort Pouch?

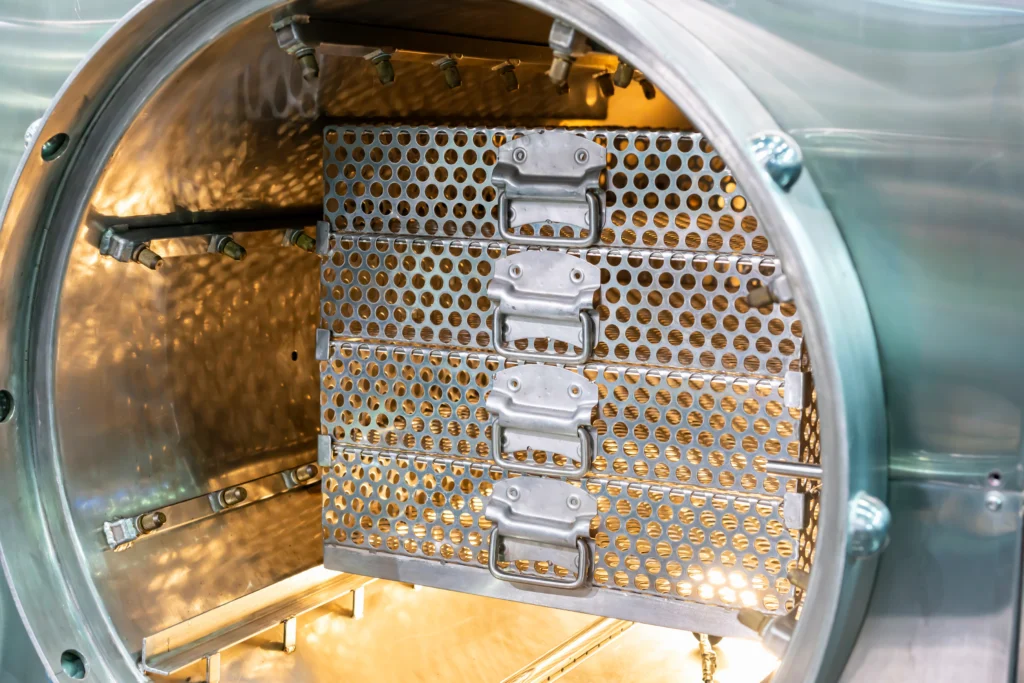

A retort pouch is a heat-resistant, multilayer laminated structure used to pack ready-to-eat foods, soups, sauces, baby food, and more. These food product packed in pouches undergo thermal processing inside retort chambers—essentially high-pressure cookers that sterilise the food at temperatures typically around 121°C for up to 15–30 minutes.

Retort process ensures commercial sterility while maintaining the convenience and lightweight nature of flexible packaging. However, the materials used must withstand extreme conditions without compromising food safety or structural integrity.

Who Uses Retort Packaging?

Retort pouches are used in retort food categories across the food industry, from ready meals and soups to wet pet food and sauces. Food manufacturers in both human and pet food sectors prefer flexible retort pouches for their ability to deliver long shelf life without refrigeration. They are especially popular with:

- Brands offering pre-cooked or shelf-stable meals

- Pet food companies seeking packaging that balances durability with easy handling

- Exporters and co-packers aiming for lightweight packaging that takes up less space

- Sustainable brands looking for eco-friendly packaging solutions to replace cans and jars

Layer Structure of a Retort Pouch

The typical retortable pouch is made from a multi-layer three or four-layer laminate with each film selected for specific functional properties to withstand high temperatures:

- Outer Layer (12–15 microns Polyester or 15–25 microns Oriented Nylon): Offers mechanical durability, heat resistance, and excellent printability. PET is more commonly used for gravure printing and must be reverse-printed to avoid ink degradation during retort.

- Barrier Layer (9–12 microns Aluminium Foil or 15–20 microns EVOH): Acts as the oxygen, light, and moisture barrier. Aluminium foil is a true barrier but less flexible; EVOH must be adequately protected against moisture, often sandwiched between polyolefins.

- Adhesive or Tie Layers (Polyurethane-based adhesive or extrusion tie resin): These layers bond different substrates together and must maintain bond strength through retort cycles without delamination.

- Inner Sealant Layer (60–100 microns Retort-grade Cast Polypropylene): Provides direct food contact, heat sealing capability, and resistance to high temperatures. CPP is preferred for its high melting point and seal integrity during retort.

Each layer is selected not only based on its standalone properties but also on how it interacts under retort conditions and high-temperature sterilization. Laminate constructions such as PET/Alu/CPP or Nylon/EVOH/PP are commonly used, depending on oxygen barrier needs and food type.

How Retort Sterilisation Works

The filled and sealed pouches are placed in a retort chamber (an industrial-grade pressure cooker). Here, packaged food is heated to 115–121°C for 15–30 minutes depending on the product type and size. This thermal process eliminates pathogens while maintaining flavour, texture, and nutrition.

To ensure safe and consistent results, several factors must be carefully managed with strict quality control:

- Internal fill temperature

- Vacuum sealing and air removal

- Counter pressure balance during cooling

- Uniform load distribution within the chamber

Any mismatch in these variables can lead to pouch deformation or — in worse cases — burst seals.

Barrier Durability

The pouch material must maintain its oxygen and water vapour barrier properties even after exposure to high-temperature retort conditions. If EVOH is used as the barrier layer, it must be protected by polyolefin or polyamide outer layers to prevent moisture-induced degradation. However, EVOH is not mandatory; aluminium foil or high-barrier polyamide structures can also serve this purpose depending on the required oxygen transmission rate (OTR).

The entire packaging material structure must be designed so that the barrier layer retains performance post-retort. Typical configurations might include PET/Alu/CPP or Nylon/high-barrier PA/PP, with total thickness ranging from 80 to 130 microns depending on food type and processing intensity. For printed structures, inks must be reverse-printed on the outermost PET or Nylon layer, which is then laminated to the rest of the structure to preserve print integrity during retort.

Design Factors for Long-Term Success

For brands looking to ensure product safety and reliability in shelf-stable food formats, working with a technically skilled packaging supplier is not optional—it’s essential. When developing or sourcing retort pouches, manufacturers and brands must consider:

- Pouch geometry (stand up pouch, gusseted, etc.) for pressure distribution

- Headspace vs. fill ratio

- Residual air elimination (vacuum sealing or nitrogen flushing)

- Retort equipment variability (pressure control, ramp-up/down cycles)

- Film ageing and storage conditions

Wraping Up

- A retort pouch is a type of flexible packaging used in high-temperature sterilization.

- Designed to replace metal cans and glass jars, retort bags offer extended shelf life and excellent barrier protection.

- These pouches are ideal for food packaging of ready meals, pet food, and other pre-cooked items.

- Stand-up pouches made for retort are lightweight, eco-friendly, and take up less space.

- The materials used in retort pouches must handle heat and pressure while preserving food quality.

- Pouches are ideal for food manufacturers looking to streamline the packaging process with modern, consumer-friendly options.

- Custom printed pouches can be designed to meet brand needs while ensuring strict food safety standards.

- Retort pouches offer a practical, sustainable, and market-ready alternative to traditional canning.

At Aropack, we specialise in designing retort packaging that meet stringent performance standards without compromising on visual appeal or sustainability. From high-barrier recyclable laminates to custom sealing solutions, our team understands the science behind the pouch—and we work closely with your product requirements to deliver packaging that performs as beautifully as it looks. Whether you’re scaling up ready meals or launching a new product, we offer the technical expertise and production flexibility to help you do it right, from day one.

Ready to talk retort packaging? Give us a call on 01233 281460 or send us an email at info@aropack.co.uk for free a consultation.